History

Take a visual tour through Safety Devices' history - click on the arrow on the image above.

1964

Former saloon car racer and founding member of the BRSCC East Anglian centre, John Aley, and his ‘right hand man’, Brian Wilkinson, designed Europe's first roll bar for John Aley after a serious roll over incident. They named the roll bar an ‘Aley Bar’.

1971

The FIA decided to make roll cages mandatory in motorsport and the homologated cage was born.

1972

Brian Wilkinson left Aley Bars and formed Safety Devices with Tony Willis and Colin Mynott. Safety Devices was established in Cherry Hinton, Cambridge.

1976

Safety Devices created the world’s first 4x4 external roll cages for Land Rover and the British Army.

1978

Safety Devices move from Cherry Hinton to larger premises on Exning Road, Newmarket. Car preparation was commissioned by works teams including British Leyland, Opel, Ford, Vauxhall, Mitsubishi and Talbot. Safety Devices would take a standard body from the production line and execute suspension modifications, turret reinforcement, widened wheel arches, seam welding, and of course, the design and installation of roll cages. Safety Devices were the leading professional chassis preparation business of the time, with a work force of approximately 25 people.

1980

The Camel Trophy turned to Safety Devices to fully equip their fleet for the first expedition across the Amazon basin. This relationship continued with Safety Devices supplying ROPS throughout the Camel Trophy era.

1985

Gerry Johnstone, ex-team manager of Dealer Team Vauxhall (DTV), became a Director of Safety Devices for a short time. Under his directive, Safety Devices were the official perparers of the Vauxhall Astra GTE, sponsored by British Telecom for the top rally driver at the time, Finnish-born Pentti Airikkala, who competed in the British round of the WRC in the Astra in 1985 and 1986.

1988

Safety Devices purchased Aley Bars.

1990

Safety Devices moved to Soham, in the Newmarket area, expanding into larger premises, streamlining the flow of production and expanding SVO (Special Vehicle Operations).

1995

Land Rover commissioned Safety Devices to develop a roll cage for their Wolf vehicles, for production of 7500 cages for The British Army. Safety Devices purchased a state-of-the-art, computer controlled robotic welder, which automatically welded the roll cages together.

2005

Under increasing pressure from the market for commercially competitive products, Safety Devices’ Managing Director, ex-works rally driver Tony Fall, moved manufacturing operations to Poland, developing a partnership with a high-quality manufacturer, who still makes Safety Devices’ ISO 9001 quality assured roll cages today.

2007

QMS International certified Safety Devices as an ISO 9001 quality assured manufacturer, certification which Safety Devices still holds today.

2011

Safety Devices was commissioned by ŠKODA to design and install a bespoke roll cage for a ŠKODA Octavia vRS. On 19 August 2011 at 07:45am, the ŠKODA Octavia vRS officially became the world's fastest 2.0-litre supercharged production car when the 600 bhp 'salt spec' racer registered a SCTA sanctioned speed of 227.070 mph on Utah's legendary Bonneville Salt Flats.

2011

Formula 1 World Champion, Sebastian Vettel, topped BBC 2 TV’s Top Gear show Formula 1 drivers' leaderboard in the F1 Drivers’ Reasonably Priced Car, equipped with a prominent Safety Devices roll cage.

2012

Safety Devices celebrates its 40th Anniversary. The business continues to grow, expanding in to new markets, particularly the 4x4 Fleet vehicle market for Oil, Mineral and Gas Exploration companies.

2014

Safety Devices move to its new 12,000 square feet premises in Mildenhall, Suffolk. This move will allow Safety Devices to expand through increased product developments, bespoke projects and more on-site installations.

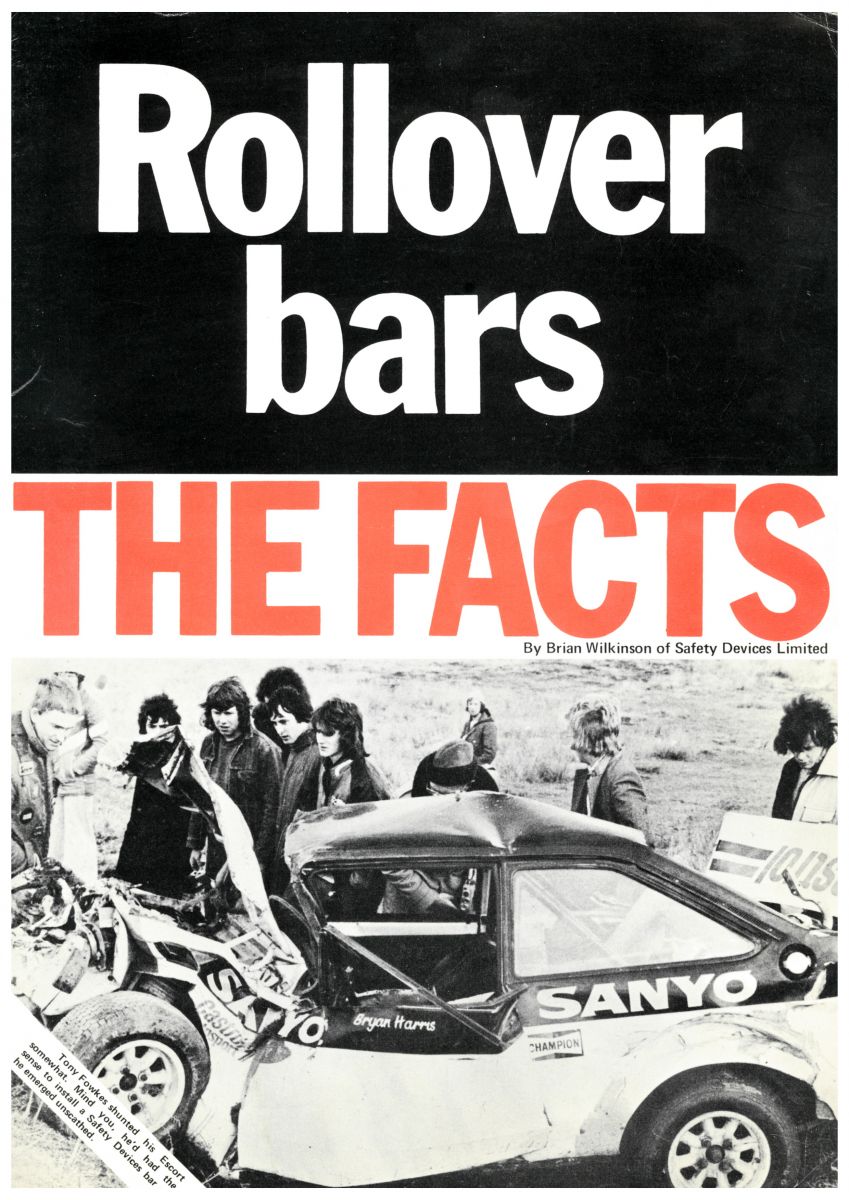

Safety Devices 1970s brochure

Click on the image below